Choosing the Right Number and Type of Inline Fans for Your Grow Room

Table of Contents

Size of Your Grow Room: Assess the dimensions of your grow room to determine the appropriate number and type of inline fans required for proper air circulation.

Assessing the dimensions of your grow room is crucial when it comes to creating an optimal environment for your plants. By understanding the size of your grow room, you can determine the appropriate number and type of inline fans required for proper air circulation. Adequate air circulation is essential for ensuring that your plants receive the necessary supply of fresh, oxygen-rich air and that stagnant air and humidity are properly managed.

When assessing the dimensions of your grow room, consider factors such as the square footage, height, and layout. These factors will help you determine the airflow requirements and the placement of inline fans to achieve uniform air distribution throughout the space. It’s important to note that different types and sizes of inline fans have varying airflow capacities, so choosing the right fan size and quantity is crucial for maintaining a healthy growing environment. Additionally, take into account any obstacles within the room, such as shelves or equipment, which may impact airflow and require additional fans or alternative placement options. By carefully assessing the size of your grow room, you can ensure optimal air circulation and create ideal conditions for your plants’ growth and development.

Here is a table that shows some examples of how many inline fans you might need for different sizes of grow rooms, assuming you use 6-inch fans with a CFM rating of 400:

| Grow Room Size (L x W x H) | Volume (cubic feet) | Number of Fans |

|---|---|---|

| 4 x 4 x 8 | 128 | 1 |

| 8 x 8 x 8 | 512 | 2 |

| 10 x 10 x 10 | 1000 | 3 |

| 12 x 12 x 12 | 1728 | 5 |

| 15 x 15 x 15 | 3375 | 9 |

Please note that this table is only a rough estimate and you may need to adjust the number of fans according to your specific conditions and preferences.

• Square footage: Measure the length and width of your grow room to determine its square footage. This will help you understand the overall size of the space and calculate the appropriate airflow requirements.

• Height: Consider the height of your grow room as well. Taller rooms may require additional inline fans or adjustments in fan placement to ensure proper air circulation throughout all levels.

• Layout: Take note of any specific layout features, such as corners or irregularities in shape, that may impact airflow patterns. These factors can influence where you place your inline fans for optimal distribution.

• Airflow requirements: Based on the dimensions of your grow room, consult with a professional or refer to manufacturer guidelines to determine how much airflow is needed for efficient ventilation. This will guide you in selecting the right type and quantity of inline fans.

• Fan sizes and capacities: Different types and sizes of inline fans have varying airflow capacities. Choose fans that match both your required airflow needs and available space within your grow room.

• Obstacles: Identify any obstacles within your grow room that could impede proper air circulation, such as shelves or equipment. Adjust fan placement accordingly or consider adding extra fans if necessary.

Below is a Small Size Grow Room with Few Inline Fans.

By carefully assessing these dimensions and factors related to your grow room, you can make informed decisions about how many inline fans are needed and where they should be placed for optimum air circulation. This attention to detail will contribute significantly to creating an ideal environment for healthy plant growth and development.

Below is a Bigger Size Grow Room with More Inline Fans.

Heat Output of Your Equipment: Consider the heat generated by your grow lights and other equipment in order to choose inline fans that can adequately dissipate the heat and maintain optimal temperature levels.

When setting up your grow room, it is crucial to consider the heat output of your equipment. Grow lights and other tools can generate significant amounts of heat, which can negatively impact the temperature balance within your grow room. Maintaining optimal temperature levels is vital for the health and growth of your plants.

Choosing inline fans that can adequately dissipate the heat is essential to ensure a stable and ideal environment for your plants. These fans help to maintain proper air circulation and prevent heat buildup. By effectively removing the excess heat, they contribute to creating a comfortable and conducive environment for your plants to thrive.

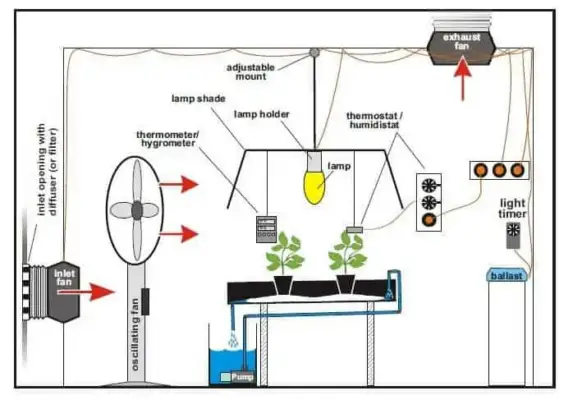

Below is a Grow Room with Grow Lights

To determine the appropriate inline fans for your setup, assess the heat output of your equipment. Consider the wattage and heat generation of your grow lights, as well as any other heat-producing devices, such as heaters or pumps. Calculate the total heat output and choose inline fans that can handle the workload. It is recommended to choose fans with higher airflow capacity to ensure efficient heat dissipation and temperature control. By carefully considering the heat output of your equipment, you can select the right inline fans to maintain ideal temperature levels in your grow room.

• When setting up your grow room, consider the heat output of your equipment

• Grow lights and other tools can generate significant amounts of heat

• Maintaining optimal temperature levels is vital for plant health and growth

• Choose inline fans that can adequately dissipate the heat

• Inline fans help maintain proper air circulation and prevent heat buildup

• Removing excess heat creates a comfortable environment for plants to thrive

• Assess the wattage and heat generation of your equipment to determine fan needs

• Calculate total heat output and choose fans capable of handling workload

• Select fans with higher airflow capacity for efficient heat dissipation

By considering the heat output of your equipment, you can select appropriate inline fans to maintain ideal temperature levels in your grow room.

Other Types of Grow Lights

Air Exchange Requirements: Calculate the desired air exchange rate for your grow room, taking into account factors such as plant density, CO2 supplementation, and humidity control.

Proper air exchange is essential for ensuring a healthy and productive growing environment in your grow room. Calculating the desired air exchange rate requires considering various factors such as plant density, CO2 supplementation, and humidity control.

To determine the ideal air exchange rate for your grow room, you need to assess the number of plants and their size or density. Plants require fresh air for photosynthesis and respiration, so a higher plant density may need a more frequent air exchange. Additionally, CO2 supplementation plays a crucial role in enhancing plant growth, and the air exchange rate should allow for the optimal distribution of CO2 throughout the room. Finally, humidity control is crucial for preventing the growth of mold and fungus, and the air exchange rate should help regulate humidity levels effectively.

• Assess the number of plants and their size or density to determine the ideal air exchange rate

• Higher plant density may require a more frequent air exchange to ensure sufficient fresh air for photosynthesis and respiration

• Consider CO2 supplementation and ensure that the air exchange rate allows for optimal distribution of CO2 throughout the grow room

• Proper humidity control is essential to prevent mold and fungus growth, so the air exchange rate should help regulate humidity levels effectively

Static Pressure: Determine the static pressure within your grow room, as this will impact the performance of your inline fans. Ensure that the fans you choose can handle the specific static pressure requirements of your setup.

Determining the static pressure within your grow room is crucial for the optimal performance of your inline fans. Static pressure refers to the resistance to airflow caused by obstructions such as filters, ducting, and bends in the system. It is important to ensure that the fans you choose can handle the specific static pressure requirements of your setup.

To determine the static pressure, you will need to measure the total equivalent length of your ducting system, including any bends and elbows. This will give you an idea of the resistance the air will encounter as it moves through the system. You can then consult the manufacturer’s specifications for the inline fans you are considering to ensure they are capable of handling the determined static pressure.

By choosing inline fans that can handle the specific static pressure requirements of your setup, you can ensure that the air circulation in your grow room remains efficient and effective. This will help to maintain optimal growing conditions for your plants and maximize their growth potential. So, take the time to determine the static pressure in your grow room and select inline fans accordingly to help your plants thrive.

• Determining the static pressure within your grow room is crucial for optimal performance

• Static pressure refers to resistance to airflow caused by obstructions in the system

• Fans must be able to handle specific static pressure requirements of your setup

• Measure total equivalent length of ducting system, including bends and elbows, to determine resistance

• Consult manufacturer’s specifications for inline fans to ensure they can handle determined static pressure

• Choosing inline fans that can handle specific static pressure requirements ensures efficient air circulation

• Efficient air circulation maintains optimal growing conditions for plants

• Select inline fans accordingly to help plants thrive.

Below is Airflow in a Grow Room

Noise Level: Evaluate the noise level produced by different inline fans and choose ones that operate at a level suitable for your grow room environment.

In the quest to create the perfect growing environment for your plants, it’s important to consider the noise level produced by different inline fans. While these fans are crucial for maintaining proper air circulation and ventilation in your grow room, they can also contribute to a significant amount of noise pollution.

When evaluating the noise level of inline fans, it’s essential to choose ones that operate at a level suitable for your grow room environment. Excessive noise can not only be annoying, but it can also disrupt the sleep patterns of nearby inhabitants or disturb the tranquility of your space. Additionally, high noise levels may indicate that the fan is working harder than necessary, which could lead to more wear and tear and potentially shorten its lifespan.

• Consider the decibel (dB) rating of different inline fans. dB is a unit used to measure the intensity of sound. Look for fans with lower dB ratings, as they will produce less noise.

• Pay attention to the manufacturer’s specifications and product descriptions when comparing inline fan options. Some manufacturers may specifically mention that their fans are designed to operate quietly.

• Read customer reviews and testimonials to get an idea of how noisy or quiet a particular inline fan is in real-world situations. Other growers’ experiences can provide valuable insights into noise levels.

• Take into account the size and power of the inline fan. Generally, larger and more powerful fans tend to produce more noise than smaller ones. If possible, opt for a fan that meets your airflow needs while still operating at a quieter level.

• Look for features such as insulated housing or rubberized mounting brackets that can help reduce vibration and minimize noise transmission from the fan motor.

• Consider using additional soundproofing measures in your grow room, such as acoustic foam panels or sound-dampening curtains, to further reduce noise levels generated by inline fans.

By carefully evaluating the noise level produced by different inline fans, you can choose ones that will create a suitable environment for your plants without causing excessive disturbance or annoyance. Remember to consider factors such as dB rating, manufacturer specifications, customer reviews, size/power of the fan, additional features like insulation or rubberized mounts, and potential soundproofing measures in order to make an informed decision about which inline fan is best suited for your grow room setup.

Here is a table that compares the noise level of different inline fans in a grow room.

| Inline Fan | Noise Level (dB) | Noise Level (Sones) | Features |

|---|---|---|---|

| TerraBloom EC | 25-30 | 0.4-0.6 | EC motor, speed controller, temperature and humidity sensor |

| Envirovent SILMV | 26-34 | 0.4-0.8 | AC motor, speed controller, mounting brackets |

| Tornado Turbo Tube | 28-38 | 0.5-1.0 | AC motor, speed controller, mounting brackets |

| Vent Axia ACM | 30-40 | 0.6-1.2 | AC motor, speed controller, mounting brackets |

AC Infinity Cloudline S4 | 28 | 0.4 | EC motor, speed controller, temperature and humidity sensor |

| Mars Hydro 4 Inch | 28 | 0.4 | AC motor, speed controller, mounting brackets |

As you can see, the noise level of different inline fans varies depending on the size, power, and features of the fan. Generally, EC motors are quieter than AC motors, and speed controllers can help reduce the noise level by adjusting the fan speed.

Energy Efficiency: Consider the energy consumption of different inline fans to minimize operational costs and reduce your environmental footprint.

When it comes to selecting inline fans for your grow room, energy efficiency should be a key consideration. By minimizing the energy consumption of your fans, you can not only save on operational costs but also reduce your environmental footprint.

Inline fans that are designed with energy efficiency in mind utilize advanced technologies to achieve optimal performance with minimal power usage. These fans are built with high-quality components and motors that are specifically engineered to deliver maximum airflow while consuming less energy. Additionally, some inline fans are equipped with intelligent speed control features that allow you to adjust the fan’s speed according to your specific needs, further enhancing energy efficiency.

• Energy-efficient inline fans are designed to minimize energy consumption

• They utilize advanced technologies for optimal performance with minimal power usage

• High-quality components and motors are used to deliver maximum airflow while consuming less energy

• Some models have intelligent speed control features for further energy efficiency

Fan Speed Control: Determine whether you require inline fans with adjustable speed settings to allow for precise control over airflow and ventilation.

Having precise control over airflow and ventilation is crucial in maintaining optimal growing conditions in your indoor garden. This is where inline fans with adjustable speed settings come into play. By allowing you to adjust the fan speed, these fans provide the flexibility to regulate the amount of air being circulated within your grow room.

The ability to adjust the fan speed is particularly important during different stages of plant growth. For instance, during the vegetative stage, plants require stronger airflow to promote healthy leaf development and prevent the buildup of excess heat and humidity. On the other hand, during the flowering stage, it may be necessary to reduce the fan speed to prevent damaging delicate flowers. With inline fans that offer adjustable speed settings, you can easily cater to the specific needs of your plants at each stage of their growth cycle.

Moreover, adjustable speed settings allow you to fine-tune ventilation to your specific grow room requirements. Whether you need to increase airflow in areas with poor ventilation or reduce air circulation in sections with sensitive plants, having the flexibility to adjust fan speed can help create a more customized and controlled environment for your plants. This level of precision in airflow management can ultimately contribute to higher yields and healthier plants in your indoor garden.

• Inline fans with adjustable speed settings provide precise control over airflow and ventilation in indoor gardens.

• Adjusting the fan speed allows for regulation of air circulation within the grow room.

• During the vegetative stage, stronger airflow is needed to promote healthy leaf development and prevent heat and humidity buildup.

• In the flowering stage, reducing fan speed can protect delicate flowers from damage.

• Adjustable speed settings cater to the specific needs of plants at different stages of their growth cycle.

• Fine-tuning ventilation based on grow room requirements is possible with adjustable fan speeds.

• Increasing airflow in poorly ventilated areas or reducing air circulation in sections with sensitive plants becomes easier.

• Customized and controlled environments created through adjustable fan speeds can lead to higher yields and healthier plants.

Ducting Length and Configuration: Take into account the length and configuration of your ducting system, as this will affect the pressure and airflow

When designing your grow room, it is essential to consider the length and configuration of your ducting system as it directly impacts the pressure and airflow within your setup. The length of the ducting plays a crucial role in determining the overall performance of your inline fans. Longer ducting systems may experience higher levels of resistance, leading to decreased airflow and compromised ventilation. On the other hand, shorter ducting systems tend to offer better airflow due to reduced resistance.

Below is a Short Ducting System

Additionally, the configuration of your ducting system influences the efficiency of air circulation within your grow room. The use of straight ducts, with minimal bends or turns, promotes smooth airflow and minimizes pressure drops. However, if you have limited space or need to navigate obstacles, it may be necessary to incorporate bends or elbows into your ducting layout. When doing so, it is vital to ensure that these components are properly sized to maintain optimal airflow and minimize any potential disruptions to the air circulation in your grow room. By carefully considering the length and configuration of your ducting system, you can effectively optimize the pressure and airflow in your grow room for healthier plant growth and improved overall performance.

• Longer ducting systems may experience higher levels of resistance, leading to decreased airflow and compromised ventilation.

• Shorter ducting systems tend to offer better airflow due to reduced resistance.

• Straight ducts with minimal bends or turns promote smooth airflow and minimize pressure drops.

• Incorporating bends or elbows into your ducting layout may be necessary if you have limited space or need to navigate obstacles.

• Ensure that any bends or elbows are properly sized to maintain optimal airflow and minimize disruptions in air circulation.

Interested in Setting up a Perfect Grow Room, Watch this video!

How do I determine the appropriate number and type of inline fans for my grow room based on its dimensions?

Assess the dimensions of your grow room to calculate the air circulation requirements. Factors such as room size, layout, and obstacles will help determine the number and type of inline fans needed. Consulting with a professional or using online calculators can assist in making an informed decision.

Why is it important to consider the heat output of my equipment when choosing inline fans?

The heat generated by grow lights and other equipment can affect the temperature levels in your grow room. It is crucial to choose inline fans that can dissipate this heat effectively to maintain optimal temperature conditions for plant growth.

How do I calculate the desired air exchange rate for my grow room?

To determine the air exchange rate, factors such as plant density, CO2 supplementation, and humidity control need to be considered. By assessing these factors and consulting resources or professionals, you can calculate the appropriate air exchange rate for your specific grow room requirements.

What is static pressure, and why is it important for inline fans?

Static pressure refers to the resistance to airflow within the ducting system. It is important to determine the static pressure within your grow room as it directly impacts the performance of your inline fans. Choosing fans that can handle the specific static pressure requirements of your setup ensures optimal airflow and ventilation.

How can I evaluate the noise level produced by different inline fans?

You can evaluate the noise level of inline fans by researching their decibel ratings or checking product specifications. It is important to choose fans that operate at a suitable noise level for your grow room environment to minimize disruptions and maintain a peaceful working environment.

Why should I consider the energy efficiency of inline fans?

Considering the energy consumption of inline fans is important to minimize operational costs and reduce your environmental footprint. Energy-efficient fans can help save on electricity bills while still providing the necessary airflow and ventilation for your grow room.

Do I need inline fans with adjustable speed settings?

Depending on your specific airflow and ventilation needs, adjustable speed settings for inline fans can offer precise control over the airflow in your grow room. It allows you to adjust the fan speed according to changing environmental conditions or plant growth stages.

How does the length and configuration of my ducting system affect pressure and airflow?

The length and configuration of your ducting system impact the pressure and airflow within your grow room. Longer ducting systems or complex configurations can introduce more resistance, resulting in decreased airflow and potentially affecting the overall performance of your inline fans. Carefully considering the layout and dimensions of your ducting system ensures optimal airflow and ventilation.