How to Make Your Own Solventless Concentrates with Pure Pressure Helix 3 Ton Rosin Press: A Review

Table of Contents

Understanding the Basics of Solventless Concentrates

Solventless concentrates have become increasingly popular in the cannabis industry, offering a clean and pure extraction method without the use of solvents. These concentrates are prized for their potency, flavor, and overall quality. But what exactly are solventless concentrates? Simply put, solventless concentrates are a form of cannabis extract that is made without the use of any chemical solvents like butane or ethanol. Instead, they rely on mechanical or heat pressure to extract the desired compounds from the plant material.

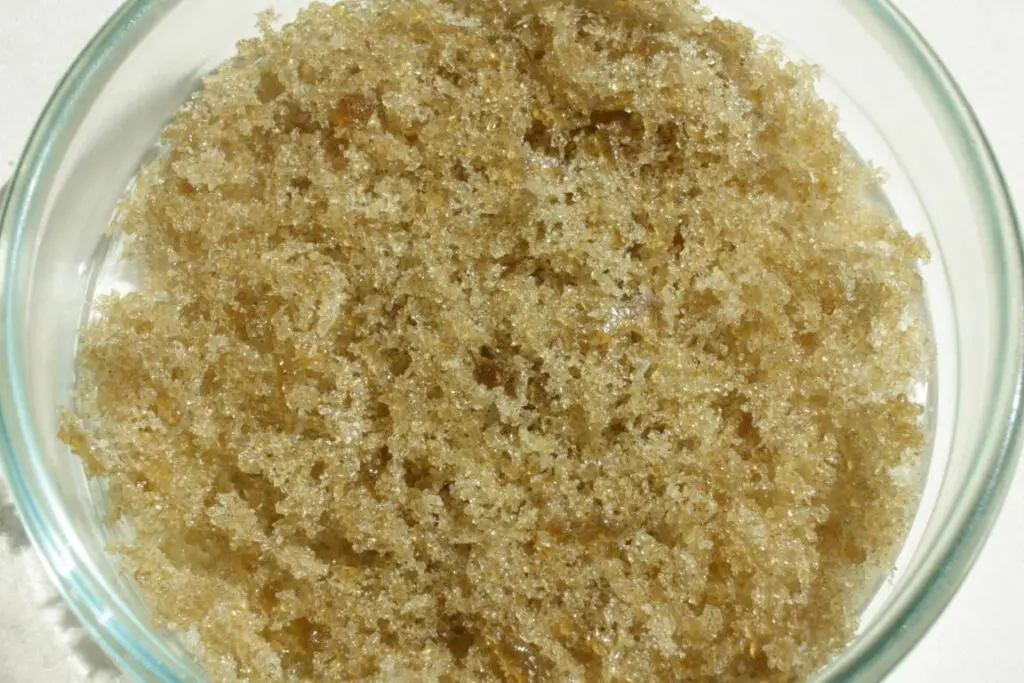

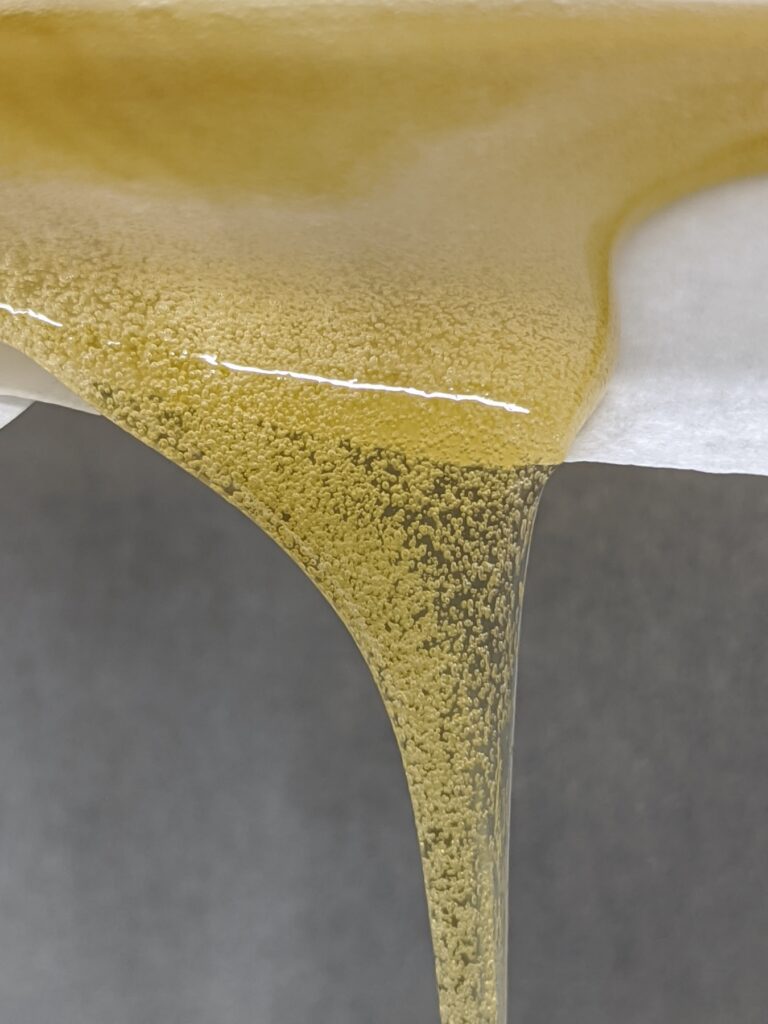

One of the most common methods of producing solventless concentrates is through the process of rosin pressing. This technique involves applying heat and pressure to cannabis flower or hash, which causes the trichomes (the resin glands containing cannabinoids and terpenes) to release their essential oils. The resulting sticky, golden-colored substance is then collected and further processed into various forms, such as rosin chips, live resin, or full melt hash. Solventless concentrates offer a more natural and holistic alternative to solvent-based extracts, as they preserve the true essence of the cannabis plant without any residual chemicals or impurities.

Exploring the Benefits of Pure Pressure Helix 3 Ton Rosin Press

The Pure Pressure Helix 3 Ton Rosin Press is one of the most advanced and efficient rosin extraction machines on the market. With its cutting-edge technology and impressive features, this rosin press offers a range of benefits for both commercial operations and home users.

One of the key benefits of the PurePressure Helix 3 Ton Rosin Press is its precision and consistency. The press is equipped with a digital control panel that allows users to set and monitor the exact temperature and pressure levels. This ensures that every extraction is performed with utmost accuracy, resulting in higher yields and superior quality concentrates. Additionally, the press is equipped with an innovative helix coil design, which evenly distributes heat and pressure throughout the material. This eliminates the risk of hot spots and ensures a uniform extraction, guaranteeing optimal results every time.

Another notable advantage of the Pure Pressure Helix 3 Ton Rosin Press is its durability and reliability. The press is constructed using high-quality materials, making it sturdy and long-lasting. It is also equipped with a powerful hydraulic system that can exert up to 3 tons of pressure, allowing for efficient and effective extraction of rosin from various materials. Whether you’re a small-scale grower or a large-scale operator, this rosin press can handle the demands of your production needs with ease. Its robust build and reliable performance make it a valuable addition to any solventless concentrate production setup.

Selecting the Right Materials for Making Solventless Concentrates

Selecting the right materials is crucial when it comes to making solventless concentrates. The quality of your starting material will directly impact the potency and overall quality of your final product.

First and foremost, it is important to use high-quality cannabis flower in order to achieve the best results. Look for strains that are known for their resinous and trichome-rich buds, as these will yield a higher concentration of cannabinoids and terpenes. Indica-dominant strains are generally preferred for solventless extraction, as they tend to have higher resin content.

Additionally, it is important to consider the moisture content of your starting material. Too much moisture can lead to excessive humidity during the pressing process, resulting in a lower quality end product. On the other hand, if the material is too dry, it can be difficult to extract a sufficient amount of resin. Aim for a moisture content of around 62-65% for optimal results.

Lastly, the size and consistency of your cannabis material also play a role in the extraction process. Small, evenly ground buds or hashish will provide a larger surface area for resin extraction and a more consistent pressing. Avoid using large chunks or stems, as they may hinder the efficiency of the process.

By selecting high-quality cannabis flower with the right moisture content and ensuring a consistent size and consistency, you are setting yourself up for success when making solventless concentrates. Remember, the quality of your starting material is the foundation of a great end product.

• Look for strains known for resinous and trichome-rich buds

• Indica-dominant strains are preferred for solventless extraction

• Consider the moisture content of your starting material

◦ Too much moisture can lead to excessive humidity during pressing process

◦ Aim for a moisture content of around 62-65%

• Pay attention to the size and consistency of your cannabis material

◦ Small, evenly ground buds or hashish provide larger surface area for resin extraction

◦ Avoid using large chunks or stems

Preparing Your Cannabis for Rosin Pressing

To prepare your cannabis for rosin pressing, it is essential to ensure that you have high-quality flower or trim to work with. Start by selecting fresh and well-cured cannabis that is free from any mold, mildew, or pests. It is advisable to use flower or trim that has been stored in a cool and dry environment to maintain its potency and flavor.

Before pressing, it is recommended to break down the cannabis into smaller pieces to increase surface area exposure. This can be done by hand or by using a grinder. However, be cautious not to grind the cannabis too finely, as this can result in excess plant material making its way into the final concentrate.

Additionally, it is important to remove any large stems or stalks, as they can hinder the extraction process and potentially damage the press. Carefully inspect the cannabis for any foreign objects or debris, ensuring a clean starting material.

By taking the time to properly prepare your cannabis before rosin pressing, you can enhance the quality and yield of your solventless concentrates.

Proper Techniques for Using the PurePressure Helix 3 Ton Rosin Press

The PurePressure Helix 3 Ton Rosin Press is a powerful tool that can help you extract high-quality solventless concentrates from your cannabis. To ensure the best results, it is essential to follow proper techniques when using this rosin press.

First and foremost, it is crucial to start with the right material. High-quality cannabis flower or hash consistently produces better yields and superior end products. Ensure that your material is properly cured and free of any contaminants before pressing.

When loading the material into the rosin press, evenly distribute it across the parchment paper. This allows for an even distribution of pressure and heat, resulting in a more efficient extraction. It is recommended to use a pollen press or similar tool to pre-press the material into small pucks, ensuring better consistency and enhanced yields.

Once your material is prepared, it is time to set the temperature and pressure on the Helix 3 Ton Rosin Press. Aim for a temperature between 180-220°F (82-104°C) and a pressure between 600-1500 PSI, depending on the specific characteristics of your material. These settings may vary slightly depending on personal preference and the desired end product.

As you begin the pressing process, apply gradual pressure to allow the oils to release slowly. This technique helps maximize yield and maintain the quality of the concentrate. It is crucial to monitor the press closely, adjusting the pressure and temperature if necessary to achieve optimal results.

Proper techniques are essential when using the PurePressure Helix 3 Ton Rosin Press. By starting with high-quality material, evenly distributing it, setting the right temperature and pressure, and applying gradual pressure during the pressing process, you can achieve superior solventless concentrates that showcase the full potential of your cannabis.

Achieving Optimal Temperature and Pressure for Maximum Yield

Temperature and pressure are two critical factors that greatly influence the yield and quality of solventless concentrates produced using the PurePressure Helix 3 Ton Rosin Press. Achieving optimal temperature and pressure is crucial for maximizing the extraction efficiency and obtaining the desired results.

When it comes to temperature, it is important to find the sweet spot that balances the release of essential oils from the plant material without causing degradation or burning. Different strains and plant materials may require slightly different temperature ranges, but generally, a temperature between 180°F to 220°F (82°C to 104°C) is considered ideal for most rosin pressing.

To ensure consistent results and avoid scorching or uneven extraction, it is recommended to pre-press your cannabis at a lower temperature and gradually increase the temperature during the pressing process. This gradual increase in heat allows the resin glands to liquefy and evenly distribute, resulting in a higher yield of quality rosin. A general guideline is to start at a lower temperature (around 160°F to 180°F) for the initial press, then gradually increase the temperature to the desired range for subsequent presses.

The next crucial factor is pressure. The PurePressure Helix 3 Ton Rosin Press offers precise control over pressure, allowing you to apply just the right amount of force to extract the most resin without damaging the plant material. It is important to find the balance between enough pressure to effectively release the resin and not applying excessive force that could lead to contamination of the final product or cause the filter bags to burst.

Experimenting with different pressure settings is key to finding the optimal pressure for your specific material. A good starting point is to apply moderate pressure initially, then slowly increase the force incrementally until you hit the desired yield. Monitoring the flow rate of the rosin and observing the color and consistency of the extracted resin can help determine if the pressure is too low or too high. Remember, finding the sweet spot may require some trial and error, but once you discover the right combination of temperature and pressure, you can achieve maximum yield and high-quality solventless concentrates.

Step-by-Step Guide to Making Solventless Concentrates with the Rosin Press

To start making solventless concentrates with the rosin press, you’ll need to gather your materials and prepare your cannabis. Begin by selecting high-quality, trichome-rich flower or hash that is fresh and well-cured. This will ensure that you extract the maximum potency and flavor from your starting material.

Next, break down the flower or hash into small pieces to increase the surface area and facilitate the extraction process. It’s important to note that the size of the material will impact the outcome, with smaller pieces typically resulting in higher yields.

Once your cannabis is prepared, it’s time to set up the rosin press. Ensure that it is clean and free of any debris or residue. Adjust the temperature and pressure settings according to the manufacturer’s guidelines or your own preferences, keeping in mind that different types of cannabis may require different conditions for optimal extraction.

Now, place the prepared cannabis between two sheets of parchment paper or rosin bags, ensuring that the material is evenly distributed and not too tightly packed. This will help to promote even heat distribution and aid in the extraction process.

With everything in place, carefully load the parchment paper or rosin bags into the press and begin applying pressure. Take note of the temperature and pressure readings on the press, as these will be crucial in achieving your desired results.

As the press applies pressure and heat, you’ll start to see the rosin being expressed from the cannabis. Monitor the process closely and adjust the temperature or pressure if necessary to ensure an efficient extraction.

Once you are satisfied with the amount of rosin collected, carefully remove it from the parchment paper or bags and transfer it to a suitable storage container. Avoid exposing the rosin to excessive heat or light, as this can degrade its quality over time.

Congratulations! You’ve successfully made solventless concentrates using a rosin press. Now, it’s time to enjoy the fruits of your labor and explore the many possibilities that these potent and flavorful extracts can offer.

Monitoring and Adjusting the Extraction Process for Desired Results

To ensure optimal results when making solventless concentrates, it is crucial to monitor and adjust the extraction process. The extraction process involves applying heat and pressure to the cannabis material, allowing the trichomes to release their resinous contents. Monitoring the process involves paying close attention to temperature and pressure levels, as well as the duration of the extraction.

Temperature plays a significant role in the extraction process, as it affects the viscosity of the resin and the release of cannabinoids and terpenes. It is important to maintain a consistent temperature throughout the extraction to ensure optimal extraction efficiency. High temperatures can cause degradation of the cannabinoids and terpenes, leading to a decrease in quality and potency. On the other hand, low temperatures may not provide enough heat to fully release the resin. By monitoring and adjusting the temperature as needed, you can achieve the desired balance between preserving the integrity of the resin and maximizing the yield of cannabinoids and terpenes.

Along with temperature, pressure also plays a crucial role in the extraction process. The pressure applied during extraction determines the rate at which the trichomes release their resin. Higher pressure typically leads to faster extraction but can also result in a higher chance of plant material contamination. It is important to find the optimal pressure that maximizes resin extraction while minimizing the risk of contamination. Monitoring the pressure and adjusting it as necessary can help ensure consistent and high-quality extraction results.

The Importance of Quality Control in Solventless Concentrate Production

One of the most crucial aspects of producing high-quality soloncentrates is implementing a rigorous quality control system. Quality control not only ensures that your products meet the highest standards of purity and potency but also helps to identify any potential issues before they become widespread. By adhering to strict quality control measures, you can consistently produce concentrates that showcase the true potential of your starting material.

| Aspect | Importance in Solventless Concentrate Production |

|---|---|

| Product Purity | Ensures the final concentrate is free from contaminants and impurities. |

| Consistency | Maintains uniformity in product characteristics, flavor, and potency. |

| Consumer Safety | Minimizes health risks by preventing harmful substances in the concentrate. |

| Legal Compliance | Adheres to regulatory standards, avoiding legal issues and ensuring market access. |

| Product Reputation | Quality control enhances the brand reputation and customer trust. |

| Efficiency in Processing | Reduces the likelihood of production delays or reprocessing due to substandard batches. |

| Cost-effectiveness | Prevents waste of raw materials and resources by catching defects early in the process. |

| Product Innovation | Facilitates experimentation and improvement in extraction techniques and end-product quality. |

| Market Competitiveness | Consistently high-quality concentrates give a competitive edge in the market. |

| Equipment Longevity | Regular quality checks prevent damage to processing equipment, ensuring long-term functionality. |

One key component of quality control is testing for residual solvents. While solventless concentrates are prized for their purity, there is always a possibility of trace amounts of solvents remaining in the final product. By conducting thorough testing using advanced analytical techniques, such as gas chromatography, you can determine the concentration of any residual solvents. This not only guarantees compliance with regulatory standards but also provides valuable insights into the extraction process, allowing you to identify and address any areas of improvement. Additionally, testing for potency and terpene profiles ensures that your concentrates possess the desired effects and aromatic profiles, giving consumers the confidence to choose your products time and time again.

Post-Processing Techniques for Refining and Enhancing Your Concentrates

Post-processing is a crucial step in refining and enhancing your solventless concentrates, allowing you to achieve a superior product with enhanced potency, flavor, and overall quality. There are various techniques that can be employed during this stage to further purify and improve your concentrates.

One effective method is winterization, which involves chilling the concentrate in a solvent, typically ethanol, to remove impurities such as plant lipids, waxes, and chlorophyll. This process is achieved by placing the concentrate in a freezer for a specific period of time, allowing the unwanted compounds to solidify and separate from the desired cannabinoids and terpenes. Afterward, the mixture is filtered through a fine micron filter or paper to remove the solid impurities, resulting in a cleaner and more refined concentrate. Winterization not only improves the overall appearance and clarity of the concentrate but also enhances its flavor profile and potency.

Storing and Preserving Your Solventless Concentrates

Properly storing and preserving your solventless concentrates is crucial to maintaining their quality and potency over time. These concentrates are delicate and can easily degrade if not stored correctly. Here are some tips to ensure that your solventless concentrates remain fresh and flavorful for longer periods:

1. Temperature Control: Keeping your concentrates in a cool and dark environment is essential to preserve their integrity. Heat and light can cause degradation and loss of potency. Consider storing your concentrates in airtight containers in a refrigerator or a dedicated cool storage area.

2. Moisture Prevention: Moisture is another enemy of solventless concentrates. Exposure to moisture can lead to mold growth and compromise the quality of your product. Make sure to store your concentrates in moisture-proof containers or pouches to protect them from humidity.

By following these storage practices, you can prolong the shelf life of your solventless concentrates and enjoy their full flavor and potency for an extended period. Always remember to label your containers with the strain type, date of production, and any other relevant information to keep track of your inventory. Proper storage is the key to preserving your hard work and ensuring a consistent experience with your solventless concentrates.

Troubleshooting Common Issues with Rosin Pressing

One of the most common issues that can arise when using a rosin press is uneven heat distribution. This can result in inconsistent yields and quality of your solventless concentrates. To troubleshoot this issue, it is important to first check the temperature of your press. Use an accurate thermometer to ensure that the heating plates are reaching the desired temperature evenly. You may also want to consider investing in a press with precise temperature control, such as the PurePressure Helix 3 Ton Rosin Press, which allows for customization and optimization of heat distribution. Additionally, inspect the alignment of your heating plates to ensure they are properly leveled, as any deviation can cause heat discrepancies. By addressing these factors, you can minimize the risk of uneven heat distribution and achieve more consistent results.

Another common issue faced when rosin pressing is low yields. If you find that your extracts are not yielding as much as expected, there are several factors to consider. Firstly, pay attention to the quality of the starting material. Lower-quality cannabis will naturally yield less desirable concentrates. Additionally, examine the temperature and pressure settings on your rosin press. Adjusting these variables can greatly impact your yield. It is important to strike a balance between temperature and pressure, as too much pressure can result in decreased yields, while too little pressure may not effectively extract the desired compounds. Furthermore, consider the duration of your press. Both under-pressing and over-pressing can affect yields, so timing your presses accurately is crucial. By methodically assessing these factors, you can troubleshoot low yield issues and optimize your rosin pressing process for maximum output.

Exploring Advanced Techniques and Tips for Experienced Rosin Press Users

When it comes to rosin pressing, experienced users are always looking for ways to enhance their techniques and achieve even better results. Here, we will explore some advanced techniques and tips that can help take your rosin pressing game to the next level.

Firstly, temperature control plays a crucial role in the extraction process. Experienced users often experiment with different temperature ranges to find the sweet spot for maximum yield and desired consistency. Lower temperatures, typically ranging from 160°F to 180°F, are known to preserve the terpene profile and flavor of the concentrate. On the other end of the spectrum, higher temperatures, around 190°F to 220°F, may yield a higher volume of rosin but can sacrifice some of the delicate terpenes. It’s essential to keep in mind that different strains may require slightly adjusted temperature settings, so don’t be afraid to fine-tune based on the specific characteristics of your starting material.

Secondly, tips for achieving consistent pressure and optimal results involve using techniques such as “double bagging” or “pre-pressing.” Double bagging involves enclosing the starting material in multiple layers of a rosin bag, which can help distribute pressure more evenly and reduce blowouts. Pre-pressing, on the other hand, involves compacting the starting material before placing it in the rosin bag. This technique helps to create a more uniform surface area, allowing for more effective heat transfer and extraction. Experimenting with different variations of these techniques and documenting the results can help experienced users fine-tune their pressing methods and achieve consistent and impressive yields.

With these advanced techniques and tips, experienced rosin press users can further enhance their extraction process and produce top-quality concentrates with maximum yield and flavor preservation. As always, it’s crucial to continue learning and experimenting to find what works best for your specific setup and starting material. By staying curious and open to new techniques, you can continually improve your rosin pressing skills and stay at the forefront of this exciting and evolving field.

for more details check the vedio:

What is the difference between solventless concentrates and concentrates made with solvents?

Solventless concentrates are made without the use of any chemicals or solvents, whereas concentrates made with solvents involve the use of substances like butane or CO2 to extract cannabinoids from the plant material.

Can any type of cannabis be used for rosin pressing?

Yes, you can use various types of cannabis for rosin pressing, including flowers, trim, or even hash.

What materials are best for making solventless concentrates?

When making solventless concentrates, it is recommended to use high-quality cannabis material with high levels of trichomes and resin production. Freshly frozen or cured flower buds are often preferred.

What temperature and pressure should I aim for to achieve maximum yield?

The optimal temperature for rosin pressing depends on the specific strain and your desired outcome. However, a starting point is typically around 190-220°F (88-104°C) for flowers and 160-190°F (71-88°C) for hash. Pressure should be adjusted accordingly, aiming for a range of 500-1500 PSI.

How can I troubleshoot common issues with rosin pressing?

If you’re experiencing issues such as low yield or poor quality rosin, it could be due to factors like incorrect temperature or pressure settings, improper material preparation, or low-quality starting material. Adjusting these variables and experimenting with different techniques can help troubleshoot such issues.

How can I store and preserve my solventless concentrates?

To store and preserve your solventless concentrates, it is best to keep them in a cool, dark, and airtight container. This helps protect against light, heat, and oxygen, which can degrade the quality and potency of the concentrates over time.

Are there any post-processing techniques to refine and enhance the quality of my concentrates?

Yes, post-processing techniques such as purging, pressing, or filtering can be used to refine and enhance the quality of your solventless concentrates. These techniques help remove impurities and improve the overall texture, flavor, and potency of the final product.

How important is quality control in solventless concentrate production?

Quality control is crucial in solventless concentrate production to ensure consistent and high-quality results. It involves monitoring factors such as temperature, pressure, material quality, and extraction times to achieve desired outcomes and maintain product consistency.

Can the PurePressure Helix 3 Ton Rosin Press be used by beginners?

While the PurePressure Helix 3 Ton Rosin Press is designed for experienced users, beginners can also use it with proper guidance and understanding of the rosin pressing process. It is important to start with small batches and gradually learn and experiment with the equipment to achieve optimal results.