Grow Room Electricity Calculator: How to Estimate and Reduce Your Energy Costs

Table of Contents

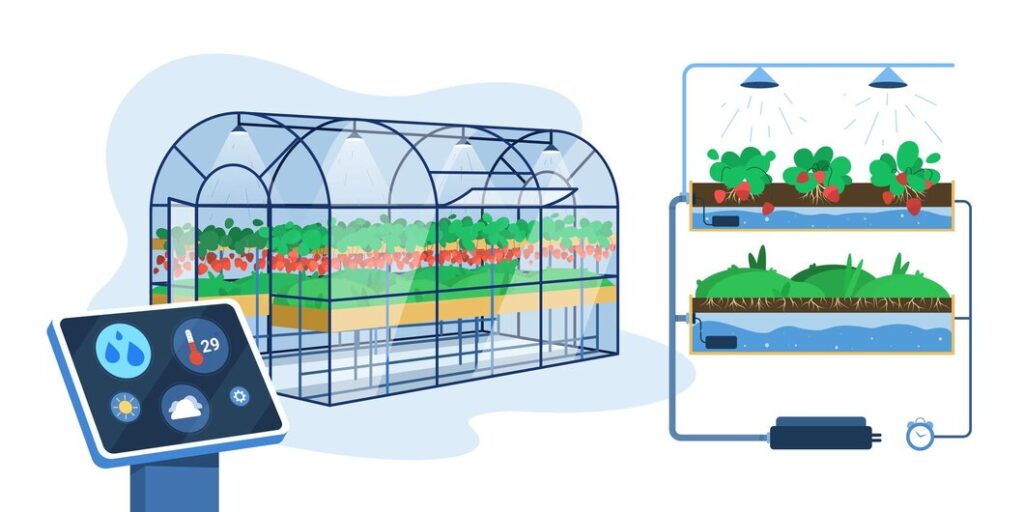

The Potential Impact of High Energy Costs on Grow Room Operations

High energy costs can have a significant impact on grow room operations. As a gardener or hydroponics enthusiast, it’s important to understand how these costs can affect your overall productivity and profitability. The increasing price of electricity, coupled with the energy-intensive nature of indoor gardening, can put a strain on your budget and limit your potential yields.

One of the major concerns is the cost of lighting. Grow lights, particularly high-intensity discharge (HID) lamps, can consume a substantial amount of energy. Depending on the size of your grow room and the lighting setup, the energy costs can quickly add up. In addition to lighting, the energy usage of HVAC systems, ventilation, irrigation, and other equipment should not be overlooked. It is crucial to carefully calculate and monitor your energy usage to identify any potential wastage or areas for improvement. By implementing energy-saving practices and investing in efficient equipment, you can mitigate the impact of high energy costs on your grow room operations and ensure long-term sustainability.

Key Factors to Consider When Calculating Energy Usage in a Grow Room

Calculating energy usage in a grow room is essential for optimizing efficiency and minimizing costs. There are several key factors to consider when determining the energy needs of your grow room.

First and foremost, lighting is a major contributor to energy consumption in indoor gardening operations. The type of light fixtures used, their wattage, and the number of hours they are operational all play a crucial role in energy usage. High-intensity discharge (HID) lights, such as metal halide (MH) and high-pressure sodium (HPS) lamps, tend to be more energy-intensive compared to light-emitting diode (LED) lights. Additionally, it’s important to consider the light intensity required for your specific plants at different growth stages. By tailoring your lighting setup to match your plants’ needs, you can reduce unnecessary energy usage.

Another factor to consider is the electrical load of equipment in your grow room, including ventilation systems, pumps, air conditioners, and dehumidifiers. Each equipment’s power rating, the duration of its operation, and its efficiency levels are all critical factors in energy calculations. It is crucial to select energy-efficient equipment and design an electrical system that can handle the estimated load while minimizing both wastage and the strain on your energy supply.

Considering these key factors when calculating energy usage in your grow room will not only help you make informed decisions about lighting and equipment selection, but also contribute to creating a sustainable and cost-effective indoor gardening operation. By understanding the energy requirements of your grow room, you can optimize energy usage, minimize costs, and cultivate a thriving garden all year round.

When calculating energy usage in a grow room, there are several key factors to consider. These factors play a crucial role in optimizing energy efficiency and ensuring healthy plant growth. Let’s break down the essential considerations:

| Factor | Description |

|---|---|

| 1. Grow Room Size | The size of the grow room determines the number of vents needed and their size. Proper ventilation ensures effective air distribution throughout the space. For smaller grow areas (less than 500 sq ft), one or two large fans may suffice, while larger spaces may require additional fans. |

| 2. Type of Fan | Industrial-grade fans provide better airflow than residential-grade fans. Their robust construction withstands higher temperatures, ensuring longevity. Some growers use a combination of different fan types to optimize airflow. |

| 3. Lighting Type | The type of lights used significantly impacts energy consumption. LED lights tend to be more energy-efficient than HID lights. Timers can help regulate light usage during different growth stages (vegetative vs. flowering). |

| 4. Temperature Requirements | Maintaining optimal temperature is critical for plant growth. HVAC systems must be designed to handle temperature fluctuations caused by lighting and other factors. |

| 5. Number of Plants | The more plants you have, the greater the energy demand. Consider the total plant count when sizing your HVAC system. |

| 6. Humidity Control | Proper humidity levels are essential. HVAC systems that manage both temperature and humidity efficiently contribute to energy savings. |

| 7. CO2 Concentration | CO2 enrichment enhances plant growth. Systems that maintain the right CO2 levels without excessive energy use are beneficial. |

| 8. System Integration | Integrating HVAC components (such as air conditioners and dehumidifiers) ensures they work harmoniously. Avoid conflicting systems that waste energy. |

| 9. Regular Maintenance | Well-maintained HVAC systems operate efficiently. Regular cleaning, filter replacement, and professional servicing are essential. |

| 10. Energy-Efficient Equipment | Choose energy-efficient HVAC equipment designed specifically for grow rooms. Properly designed systems can reduce electricity bills by up to 50% while supporting healthy plant growth. |

Remember that a well-designed HVAC system not only maintains optimal conditions but also contributes to the overall profitability of your grow operation. By considering these factors, you can make informed decisions to minimize energy consumption and maximize yields.

The Role of Equipment Selection in Reducing Energy Consumption

Equipment selection plays a crucial role in reducing energy consumption in grow room operations. Choosing the right equipment can significantly impact energy efficiency and contribute to cost savings in the long term. When selecting equipment, it is important to consider both energy efficiency ratings and the specific needs of your grow room.

One key factor to consider is the energy efficiency rating of the equipment. Look out for Energy Star certified products, as they meet strict energy efficiency standards set by the Environmental Protection Agency. These products are designed to consume less energy while still providing optimal performance. By choosing energy-efficient equipment, you can minimize electricity usage and lower your energy bills. Additionally, investing in high-quality equipment can lead to better performance and longevity, further reducing the need for replacements and repairs.

How to Properly Size and Install Electrical Systems in a Grow Room

When it comes to setting up a grow room, properly sizing and installing the electrical systems is crucial for the success of your indoor gardening operations. This involves careful planning and understanding of your specific needs in terms of lighting, ventilation, and other electrical equipment.

First and foremost, it is important to calculate the total power requirements of your grow room. This can be determined by adding up the wattage of all the electrical devices that will be used, such as grow lights, fans, pumps, and heaters. It is recommended to oversize your electrical system by at least 20% to account for any future expansion or additional equipment that may be needed.

Next, you need to ensure that the electrical system is properly installed to meet both safety and efficiency standards. It is recommended to hire a licensed electrician who has experience in working with grow room setups. They will ensure that the wiring is done correctly, outlets are properly grounded, and circuit breakers are appropriately sized to handle the load.

In addition, consider using a dedicated circuit for each major electrical component in your grow room. This helps to avoid overloading circuits and reduces the risk of electrical failures or malfunctions. It is also important to label all circuits and breakers for easy identification and troubleshooting.

By properly sizing and installing the electrical systems in your grow room, you can ensure a safe and efficient operation. This will not only protect your plants and equipment but also contribute to reducing energy waste and keeping your energy costs in check.

Tips for Optimizing Lighting Systems to Minimize Energy Usage

When it comes to optimizing lighting systems in a grow room to minimize energy usage, there are several key tips to keep in mind. Firstly, consider investing in high-efficiency LED lights, which consume significantly less energy compared to traditional lighting options. LED lights not only provide the right spectrum and intensity of light for healthy plant growth but also have a longer lifespan, reducing the need for frequent replacements.

Another important aspect to consider is the proper placement and arrangement of the lights in the grow room. By strategically positioning the lights, you can ensure optimal coverage and distribution of light, minimizing wasted energy. Additionally, using reflective materials, such as Mylar or aluminum foil, on the walls and ceiling can help enhance light reflection and improve overall efficiency.

Furthermore, implementing a timer system for your lighting setup can further reduce energy consumption. By programming the lights to operate on specific schedules based on the growth stage of the plants, you can avoid unnecessary energy usage during periods when the lights are not required.

By implementing these tips, gardeners and cultivators can optimize their lighting systems to minimize energy usage while still providing the ideal light conditions for healthy and productive plant growth.

The Benefits of Implementing a Timer System for Lighting and HVAC Equipment

Implementing a timer system for lighting and HVAC equipment in a grow room can provide numerous benefits for growers. One of the main advantages is the ability to automate the on/off cycles of these systems, leading to significant energy savings. By programming the timers to operate during specific periods, growers can ensure that lights and HVAC equipment are only running when necessary, reducing unnecessary energy consumption.

Timers can also help maintain consistency in light and temperature levels, which is crucial for healthy plant growth. By setting timers to align with the plants’ natural light and dark cycles, growers can create optimal growing conditions without the need for constant monitoring. This not only saves time but also minimizes the risk of human error in adjusting the lighting and HVAC systems.

In addition, implementing timers can improve the overall lifespan of lighting and HVAC equipment. Continuous operation can cause wear and tear, leading to frequent replacements and maintenance costs. With timers, growers can extend the lifespan of their equipment by reducing usage during periods when it is not needed.

Ultimately, the benefits of implementing a timer system for lighting and HVAC equipment in a grow room are multifaceted. From energy savings and improved efficiency to maintaining ideal growing conditions, timers can enhance the overall productivity and sustainability of gardening operations.

The Importance of Insulation and Air Sealing in Controlling Energy Costs

Insulation and air sealing are essential components in controlling energy costs for a grow room. Proper insulation helps to maintain a consistent temperature and reduce heat transfer, ensuring that energy used for heating or cooling is maximized. By creating a thermal barrier, insulation minimizes heat loss during colder months and restricts heat gain during warmer months. This not only promotes a more stable and controlled environment for plant growth but also significantly reduces the demand on heating, ventilation, and air conditioning (HVAC) systems.

Air sealing, on the other hand, focuses on preventing any unwanted air infiltration or exfiltration in the grow room. Small cracks, gaps, or holes in walls, ceilings, doors, and windows can allow conditioned air to escape or unconditioned air to enter, leading to energy wastage. Through careful sealing of these areas, growers can reduce the workload on HVAC systems and maintain the desired temperature and humidity levels more efficiently. The combination of proper insulation and air sealing establishes an effective energy-saving strategy that not only reduces operational costs but also contributes to a more sustainable and environmentally friendly grow room operation.

When it comes to controlling energy costs, insulation and air sealing play crucial roles. Let’s delve into why they matter:

| Factor | Importance |

|---|---|

| 1. Energy Savings | Proper insulation and air sealing can lead to significant energy savings. By preventing air leaks and maintaining a well-sealed envelope, homeowners can save up to 10% on their annual energy bills. |

| 2. Comfort Enhancement | Insulation keeps homes warm in winter and cool in summer. It ensures comfort during extreme weather conditions. |

| 3. Noise Reduction | A well-insulated and sealed home reduces noise from outside, creating a quieter living environment. |

| 4. Pest Prevention | Effective insulation and air sealing minimize gaps that pests (such as insects or rodents) can exploit to enter your home. |

| 5. Durability | Insulation prevents moisture from entering walls, enhancing the durability of your home’s structure. |

| 6. Ice Dam Prevention | Proper insulation and sealing reduce the chances of ice dams forming on roofs during snowy climates. |

| 7. Overall Efficiency | Combining air sealing and insulation maximizes energy efficiency, making your home more environmentally friendly. |

Remember, addressing both insulation and air sealing ensures not only cost savings but also a more comfortable and resilient living space.

Strategies for Efficiently Cooling and Ventilating a Grow Room

Efficiently cooling and ventilating a grow room is crucial for maintaining optimal conditions for plant growth. High temperatures can negatively impact plant health and growth, while poor ventilation can lead to stagnant air and increased humidity levels. To ensure effective cooling and ventilation, there are several strategies that growers can implement.

Firstly, it is essential to choose the right type and size of grow room fans. Installing exhaust fans and intake fans strategically can help in creating proper air circulation. Exhaust fans expel hot air out of the grow room, while intake fans bring in fresh air. By positioning these fans appropriately, growers can create a constant flow of air, ensuring a cooler and well-ventilated environment.

In addition, utilizing air conditioners or evaporative coolers can further aid in maintaining ideal temperatures. These cooling systems help to regulate the temperature and humidity levels inside the grow room. Implementing a thermostat or a temperature controller can ensure precise temperature management, allowing growers to adjust settings based on their specific crop requirements.

Furthermore, it is essential to consider the layout and organization of the grow room. Placing plants in a way that allows for adequate airflow between them can contribute to better cooling and ventilation. By avoiding overcrowding and ensuring proper spacing, growers can prevent hotspots and improve air circulation throughout the entire space.

Lastly, monitoring and managing humidity levels is crucial. High humidity can increase the risk of mold and mildew, which can damage crops. Implementing dehumidifiers or using air conditioners with built-in dehumidifying capabilities can help control humidity levels effectively.

By employing these strategies, growers can efficiently cool and ventilate their grow rooms, creating an ideal environment for healthy plant growth.

The Role of Data Monitoring and Analysis in Identifying Energy-saving Opportunities

Data monitoring and analysis play a crucial role in identifying energy-saving opportunities in grow room operations. By collecting and analyzing data on energy consumption patterns, growers can gain valuable insights into their energy usage and make informed decisions on how to optimize it.

One of the key benefits of data monitoring and analysis is the ability to pinpoint areas of excessive energy consumption. Through the use of smart meters, sensors, and monitoring software, growers can track the energy usage of different equipment and systems in their grow room. This data can then be analyzed to identify any inefficiencies or patterns of high energy consumption. For example, it may reveal that certain lighting systems or HVAC equipment are consuming more energy than necessary, highlighting the need for upgrades or adjustments to optimize energy usage.

In addition to identifying areas of high energy consumption, data monitoring and analysis also enable growers to measure the effectiveness of energy-saving measures they have implemented. By comparing energy usage before and after making changes, growers can determine the impact of their efforts and fine-tune their strategies accordingly. This iterative process allows for continuous improvement and refinement of energy-saving practices, leading to greater efficiency and cost savings in the long run. With data monitoring and analysis, growers can make evidence-based decisions that maximize energy efficiency and minimize operational costs, ultimately contributing to sustainable and environmentally conscious grow room operations.

Common Energy-wasting Practices to Avoid in Grow Room Operations

When operating a grow room, it is important to be aware of common energy-wasting practices that can have a significant impact on your energy consumption and costs. One common mistake is using outdated lighting fixtures that are not energy-efficient. Traditional high-intensity discharge (HID) lights, such as metal halide or high-pressure sodium lamps, consume a lot of energy and generate a significant amount of heat. This not only puts a strain on your electrical system and increases cooling needs but also wastes valuable energy. By transitioning to more energy-efficient lighting options, such as light-emitting diodes (LEDs), you can significantly reduce your energy usage while still providing optimal light conditions for your plants. LED lights consume less electricity and generate less heat, making them a more sustainable choice for grow room operations.

Another energy-wasting practice to avoid is overcooling or over-heating your grow room. It is essential to maintain adequate temperature and humidity levels for optimal plant growth, but excessive cooling or heating can lead to unnecessary energy usage. To avoid this, make sure to properly size and install your HVAC system based on the specific needs of your grow room. Additionally, using insulation and air sealing techniques can help prevent heat and cold air from escaping, ensuring that your climate control efforts are efficient and effective. By finding the right balance between temperature control and energy consumption, you can maximize energy savings in your grow room.

By being mindful of these common energy-wasting practices and implementing energy-efficient alternatives and strategies, you can minimize energy usage and reduce costs in your grow room operations. Ensuring that your lighting system is energy-efficient and properly sized, as well as optimizing temperature control with appropriate HVAC equipment and insulation, are crucial steps towards achieving sustainable and cost-effective cultivation practices. By making these changes, you can not only lower your environmental impact but also improve the financial viability of your grow room.

Tips for Conducting an Energy Audit in Your Grow Room

When it comes to conducting an energy audit in your grow room, there are several key tips to keep in mind. First and foremost, it’s important to start by examining your energy bills and tracking your usage over a specific timeframe. This will give you a clear idea of your current energy consumption patterns and help you identify areas for potential improvement.

Next, it’s crucial to thoroughly inspect your grow room to identify any energy leaks or inefficiencies. Check for drafts, inadequate insulation, and gaps in windows or doors that could be contributing to heat or energy loss. Additionally, pay attention to the layout and organization of your equipment, as improper placement can hinder airflow and increase energy demands.

After assessing your current energy usage and identifying areas for improvement, consider implementing energy-efficient technologies and practices. This can include investing in energy-efficient lighting systems, HVAC systems, and timers for controlling equipment usage. Furthermore, optimizing your lighting systems and properly sizing and installing electrical systems can significantly reduce your energy consumption.

By following these tips for conducting an energy audit in your grow room, you can identify areas of energy waste and implement strategies to reduce your energy consumption. Not only will this help you save money on energy costs, but it will also contribute to a more sustainable and environmentally-friendly grow room operation.

Understanding the Relationship Between Temperature and Humidity Control and Energy Consumption

Temperature and humidity control play a crucial role in the success of any grow room operation. Not only do they affect the overall health and growth of plants, but they also have a direct impact on energy consumption. Maintaining optimal temperature and humidity levels can help minimize unnecessary energy usage and reduce costs.

When it comes to temperature control, it’s important to understand the concept of the “sweet spot” for different types of plants. Each plant has an ideal temperature range for optimal growth, and deviating from this range can lead to reduced productivity and increased energy consumption. By using temperature control systems, such as thermostats and climate control devices, growers can ensure that their plants are kept within the desired temperature range, avoiding unnecessary energy usage and ensuring a favorable environment for plant growth.

Humidity control is equally important, as it affects transpiration rates and the overall moisture content in the grow room. High humidity levels can lead to excess moisture, which not only poses a risk of mold and mildew growth but also increases the workload on HVAC systems, resulting in higher energy consumption. On the other hand, low humidity levels can cause plants to lose moisture rapidly, leading to dehydration and stunted growth. By carefully monitoring and adjusting humidity levels using humidifiers or dehumidifiers, growers can strike the right balance and minimize energy wastage, while promoting healthy plant development.

In conclusion, understanding and effectively managing the relationship between temperature and humidity control can have significant impacts on energy consumption within a grow room. By implementing proper temperature and humidity control systems and maintaining the optimal environment for plant growth, growers can not only ensure healthy and thriving crops but also trim down their energy costs in the long run.

The Benefits of Using Energy-efficient Grow Lights and HVAC Systems

Energy-efficient grow lights and HVAC systems have tremendous benefits in both reducing energy consumption and improving overall grow room operations. By investing in energy-efficient technology, growers can significantly decrease their electricity bills while maintaining optimal growing conditions for their plants.

One notable benefit of using energy-efficient grow lights is their ability to produce more light and less heat compared to traditional lighting systems. LED grow lights, for example, convert a higher percentage of energy into usable light for plant growth, resulting in less wasted energy as heat. This not only reduces the need for additional cooling systems to dissipate excess heat but also creates a more comfortable environment for plants, promoting healthier growth and higher yields.

Furthermore, energy-efficient HVAC systems play a critical role in maintaining precise temperature and humidity levels within the grow room. These systems are designed to use less energy without sacrificing performance, resulting in lower electricity costs. By effectively controlling the temperature and humidity, growers can optimize plant growth, reduce the risk of diseases, and create an ideal environment for achieving desired crop quality.

Overall, investing in energy-efficient grow lights and HVAC systems not only offers economic advantages in terms of energy savings but also promotes sustainable and environmentally conscious practices. It allows growers to optimize their operations, increase productivity, and contribute to a greener future.

How to Calculate and Track Your Grow Room’s Energy Consumption

Calculating and tracking your grow room’s energy consumption is an essential step in optimizing your operations and minimizing costs. By understanding how much energy your grow room consumes, you can identify opportunities for improvement and implement strategies to maximize efficiency.

To calculate your grow room’s energy consumption, start by identifying all the equipment and systems that require electricity, such as lighting fixtures, HVAC systems, fans, pumps, and controllers. Determine their wattage ratings and usage duration. Add up the total wattage and multiply it by the number of hours each equipment or system operates daily. This will give you the energy used in watt-hours (Wh) per day.

Tracking your energy consumption over time allows you to monitor trends, identify patterns, and spot any irregularities. It is a valuable tool for assessing the effectiveness of energy-saving measures and adjusting your operations accordingly. Consider installing energy meters or using smart plugs that provide real-time energy usage data. This information can be logged and analyzed to determine how changes in your cultivation practices or equipment impact energy consumption. Regularly reviewing and interpreting this data will help you make informed decisions and continuously improve your grow room’s energy efficiency.

Implementing Energy-saving Practices and Technologies in Your Grow Room

Implementing energy-saving practices and technologies in your grow room is a crucial step towards optimizing operations and reducing costs. By taking proactive measures to minimize energy consumption, you not only contribute to environmental sustainability but also maximize your returns on investment. So, what are some effective strategies to consider?

First and foremost, optimizing lighting systems is key. Choosing energy-efficient grow lights, such as LED or HPS lights, can significantly reduce electricity usage without compromising plant health and growth. Additionally, implementing a timer system for lighting and HVAC equipment allows for precise control, minimizing unnecessary energy consumption during non-essential periods.

Furthermore, insulation and air sealing play a vital role in controlling energy costs. By properly insulating your grow room and sealing any air leaks, you can prevent heat loss or gain, maintaining a stable environment for your plants while decreasing reliance on heating or cooling systems. Strategic use of reflective materials can also enhance light distribution, minimizing the need for additional lighting fixtures.

Please do watch video!

What is the potential impact of high energy costs on grow room operations?

High energy costs can significantly impact the profitability of a grow room operation, as energy consumption is one of the major expenses. It can lead to reduced profit margins and make it difficult for growers to remain competitive in the market.

How can I calculate energy usage in my grow room?

When calculating energy usage in a grow room, key factors to consider include the wattage of equipment, the number of hours it is in operation, and the electricity rate. Multiply the wattage by the number of hours and divide by 1,000 to get the kilowatt-hour (kWh) usage. Then, multiply the kWh by the electricity rate to determine the energy cost.

How can equipment selection help reduce energy consumption in a grow room?

Choosing energy-efficient equipment, such as LED grow lights and high-efficiency HVAC systems, can significantly reduce energy consumption in a grow room. These technologies use less electricity while providing the necessary lighting and climate control, leading to lower energy costs.

What should I consider when sizing and installing electrical systems in a grow room?

When sizing and installing electrical systems, it is crucial to consider the power requirements of all the equipment, as well as any future expansion plans. Working with a qualified electrician is recommended to ensure the electrical system is properly designed, safely installed, and meets local building codes.

How can I optimize lighting systems to minimize energy usage in my grow room?

To minimize energy usage, consider using energy-efficient lighting technologies like LED grow lights. Additionally, implementing a timer system that automatically controls the lighting schedule based on the plant’s needs can reduce unnecessary energy consumption.

What are the benefits of implementing a timer system for lighting and HVAC equipment?

Implementing a timer system allows growers to automate the operation of lighting and HVAC equipment, ensuring they are only running when needed. This can reduce energy waste, improve efficiency, and provide consistent environmental conditions for optimal plant growth.

How does insulation and air sealing contribute to controlling energy costs in a grow room?

Insulation and air sealing help prevent the loss of conditioned air and the intrusion of outside air, reducing the load on HVAC systems. By creating a more controlled environment, growers can minimize the energy required for cooling or heating and maintain stable conditions for their plants.

What strategies can I use to efficiently cool and ventilate my grow room?

Efficient cooling and ventilation can be achieved by properly sizing and positioning fans and ductwork, implementing air circulation strategies, and using energy-efficient HVAC systems. It’s also important to manage heat-producing equipment and optimize airflow patterns within the grow room.

How can data monitoring and analysis help identify energy-saving opportunities in a grow room?

Data monitoring and analysis systems can track energy consumption patterns, identify energy-intensive equipment or processes, and pinpoint areas for improvement. By analyzing this data, growers can make informed decisions to optimize energy usage and reduce costs.

What are some common energy-wasting practices to avoid in grow room operations?

Some common energy-wasting practices to avoid include over-lighting the grow room, poorly maintained HVAC systems, inadequate insulation, inefficient air circulation, and running equipment during non-productive hours. Regular maintenance and monitoring can help identify and rectify such wasteful practices.

How can I conduct an energy audit in my grow room?

Conducting an energy audit involves assessing all energy-consuming components in the grow room, tracking their usage, and identifying areas for improvement. It may include analyzing energy bills, inspecting equipment, and monitoring environmental conditions to identify opportunities for energy savings.

What is the relationship between temperature and humidity control and energy consumption?

Temperature and humidity control in a grow room require the use of HVAC systems, which consume a significant amount of energy. The more precise and tightly controlled the temperature and humidity levels need to be, the more energy will be required for conditioning the air and maintaining the desired conditions.

What are the benefits of using energy-efficient grow lights and HVAC systems?

Using energy-efficient grow lights and HVAC systems can result in significant energy savings and cost reductions. They consume less electricity, produce less heat, and often have longer lifespans, which can contribute to improved profitability and sustainability in grow room operations.

How can I calculate and track my grow room’s energy consumption?

To calculate and track energy consumption, start by gathering data on equipment wattages, hours of operation, and energy rates. Use this information to calculate the kilowatt-hour (kWh) usage and multiply it by the electricity rate to determine energy costs. Regularly monitor and record this data for tracking purposes.

How can I implement energy-saving practices and technologies in my grow room?

Implementing energy-saving practices and technologies involves considering factors such as equipment selection, electrical system design, lighting optimization, insulation and air sealing, efficient cooling and ventilation, data monitoring, and using energy-efficient equipment. By taking these steps, growers can reduce energy consumption and lower operating costs.

Nicole Burke is a dynamic writer at SouthElMonteHydroponics, fueled by her passion for horticulture and environmental sustainability. Armed with a degree in Environmental Science from a renowned institution, Nicole’s expertise lies in hydroponic gardening, organic farming, and biodiversity conservation. Her insatiable curiosity and love for nature drive her to explore innovative techniques in hydroponics, seeking to revolutionize the way we grow crops in urban environments. Nicole’s writing reflects her deep commitment to promoting eco-conscious practices and fostering a deeper connection between humans and the natural world. Through her engaging storytelling, she inspires others to embrace sustainable living and harness the power of hydroponics for a greener future.